Carbon fabric 160 g/m² (twill, non-shift finish) 100 cm

Технические характеристики

USA: width 39.37", weight 4.7 oz/yd²

Fibre: Torayca T 300 J or equivalent in 200 tex (3k)

Style 442

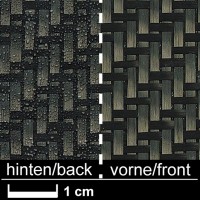

Weave: twill weave

Width: 100 cm

Basic weight 160 g/m² + 13 g/m² EP binder

Application:

Standard reinforcement fabric for modelling, motor sports, ship construction, and sporting equipment.

The EP binder prevents slippage, so cut pieces do not lose threads. Heat (pressure mould) can be used to preform the fabric before impregnation with resin. Specifically for carbon designs in automotive engineering.Even an iron on the surface (eg during coating of surfaces) is possible. The fabric will be formed only and has additionally to be impregnated with resin.

For technical reasons, the finishing of the fabric with EP slightly shifts the yarn, because the tissue must be rewound completely. An absolutely uniform web image can not be guaranteed over the entire length of roll.

Information about application eWiki.

Calculated data for hand laminates with 35 volume percent fibres:

Resin consumption: 184 g/m², laminate thickness: 0,257 mm, laminate weight: 357 g/m²